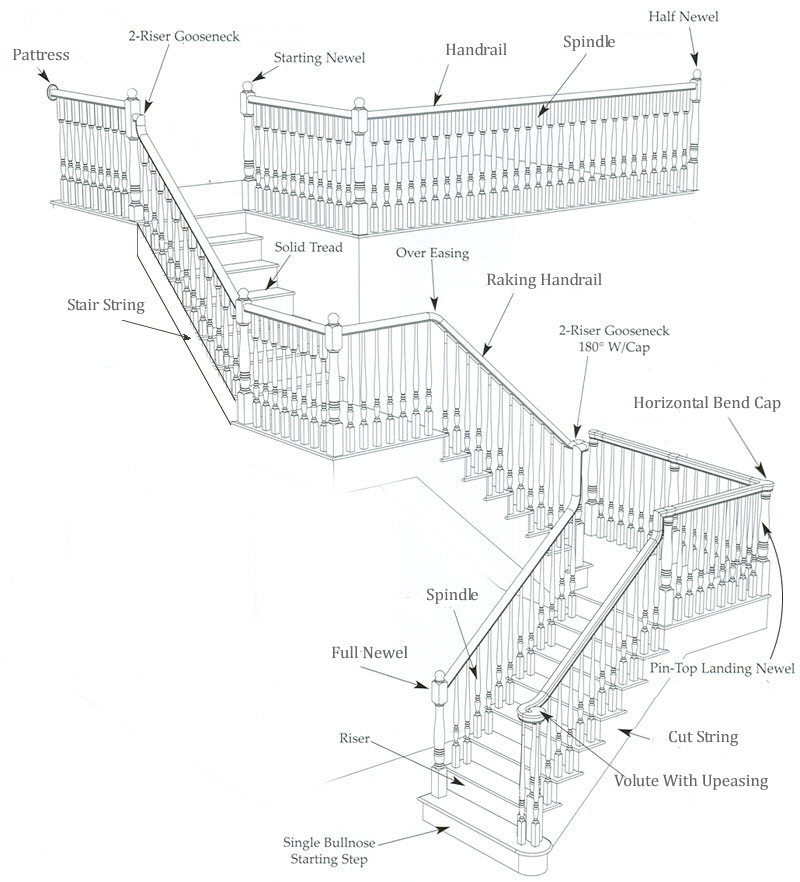

FITTING STAIR PARTS

Many clients will use a tradesman to fit stair parts, however, it is not beyond the scope of a competent D.I.Y.er to fit stair parts to a very high standard. Most of the examples shown on our gallery page are self-fitted.

The starting point is fitting the Newel posts.

For a new installation the newels would be supplied fitted to the staircase, this can be done either as full newels or newels bases with the top part to be fitted later, after all the heavy work of fixing the stairs is completed. Consulting with your staircase manufacturer will help here.

When updating an old staircase, fitting newel posts can get a little complicated, the bottom newel of the stairs can usually be completely removed and replaced with a full newel. The upper newel posts are usually fixed in a position so that they are holding up the stairs; it is rare that these newels can be removed completely. The normal way of dealing with this problem is to cut the newel around 200mm above floor level and replace the upper part with a drop-in newel of your chosen design.

Sadly this will leave you with an original newel base 'on show'. If the finished project is to be painted, this is not a problem, however if the project calls for a polished finish and timber has been changed, say from Pine to Oak, it can be difficult to cover up the original bases.

Over the years we have developed several methods of dealing with the original bases and, depending on the design and location of the stairs we are very happy to help at the planning stage to offer help in dealing with this problem.

Some staircase designs will need a special newel post in order to deal with changes of direction, the most common being the quarter turn newel, used when the stairs turn through 90 degrees and rise up one step. 'Kite winder' and 'pulpit ends' also require special newel posts all of which can be accommodated from our range of newel posts.

After the newel posts are fitted the next stage is the handrails.

With the advent of modern glues, most joiners these days would screw and glue the handrail to the newel posts.

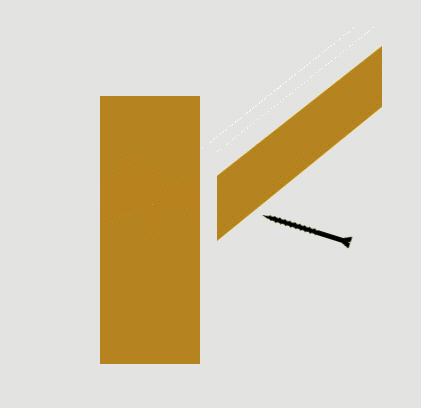

At the bottom the rail is screwed from the underside, and the screw hole is then covered by the fillet. This gives a totally invisible fixing.

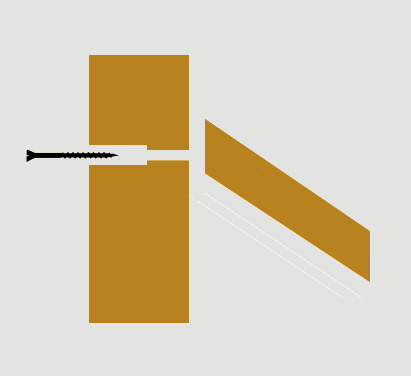

At the top, or on a level landing, the rail is fixed by screwing through the newel posts; the screw hole is counter bored 12mm and plugged with a cross grain plug, which gives an almost invisible fixing.

An alternative to screwing hand rails to the newel post is to use traditional handrail bolts, we are happy to supply these along with full instructions for their use.

We offer a full range of continuous hand rail components; this system removes the need for finials on the newel posts, allowing your hand to run the full length of the stairs and landing without letting go. An added benefit is that it is almost impossible to hang coats on the newel at the foot of the stairs!

A continuous hand rail can be designed to fit most staircase designs and we are happy to offer any help in choosing the correct components.

Fitting spindles is the final job.

Once the hand rail and newels are fixed, a base rail is usually screwed to the string of the stair and along the floor of the landing. Spindles are fixed into a groove on the under side of the hand rail and the top of the base rail. Fillet spacers are provided to be cut to length to fit in the groove between the spindles and bead of glue is all that is required to fix the spindles.

An exception to fitting base rail to the stair string is a cut string stair, see below, in this case, the spindles are dowelled into the tread of the stairs. One thing to remember on cut string stairs is that the back spindle on each step must be longer in order to follow the shape of the stairs.

The final job after fitting is to polish or paint your stair parts, this is very much a personal choice and not our area of expertise. One word of caution however, wire wool must never ever be used when polishing Oak. Iron, water and Oak will make a purple dye which cannot be removed from oak.

GLOSSARY